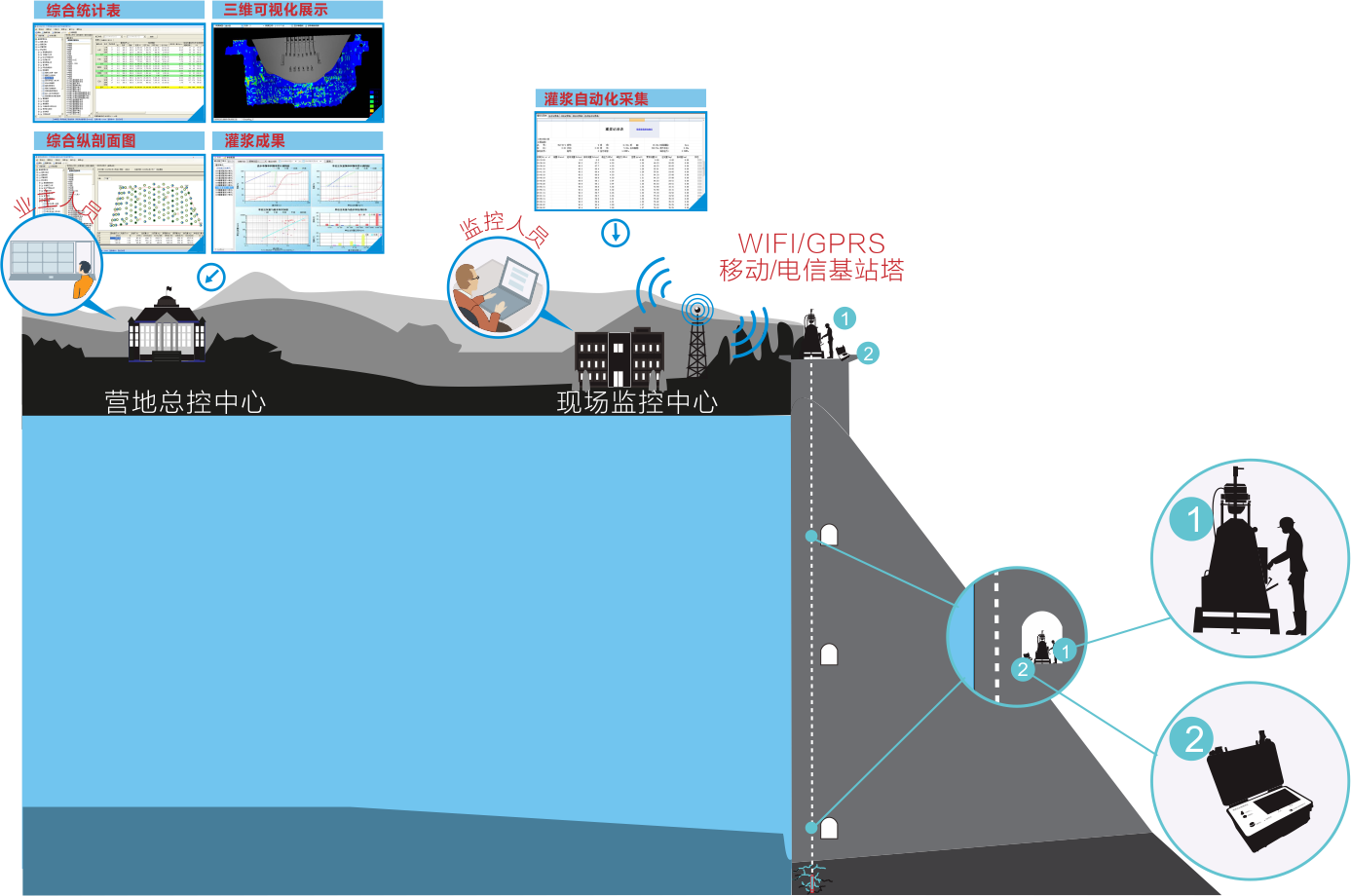

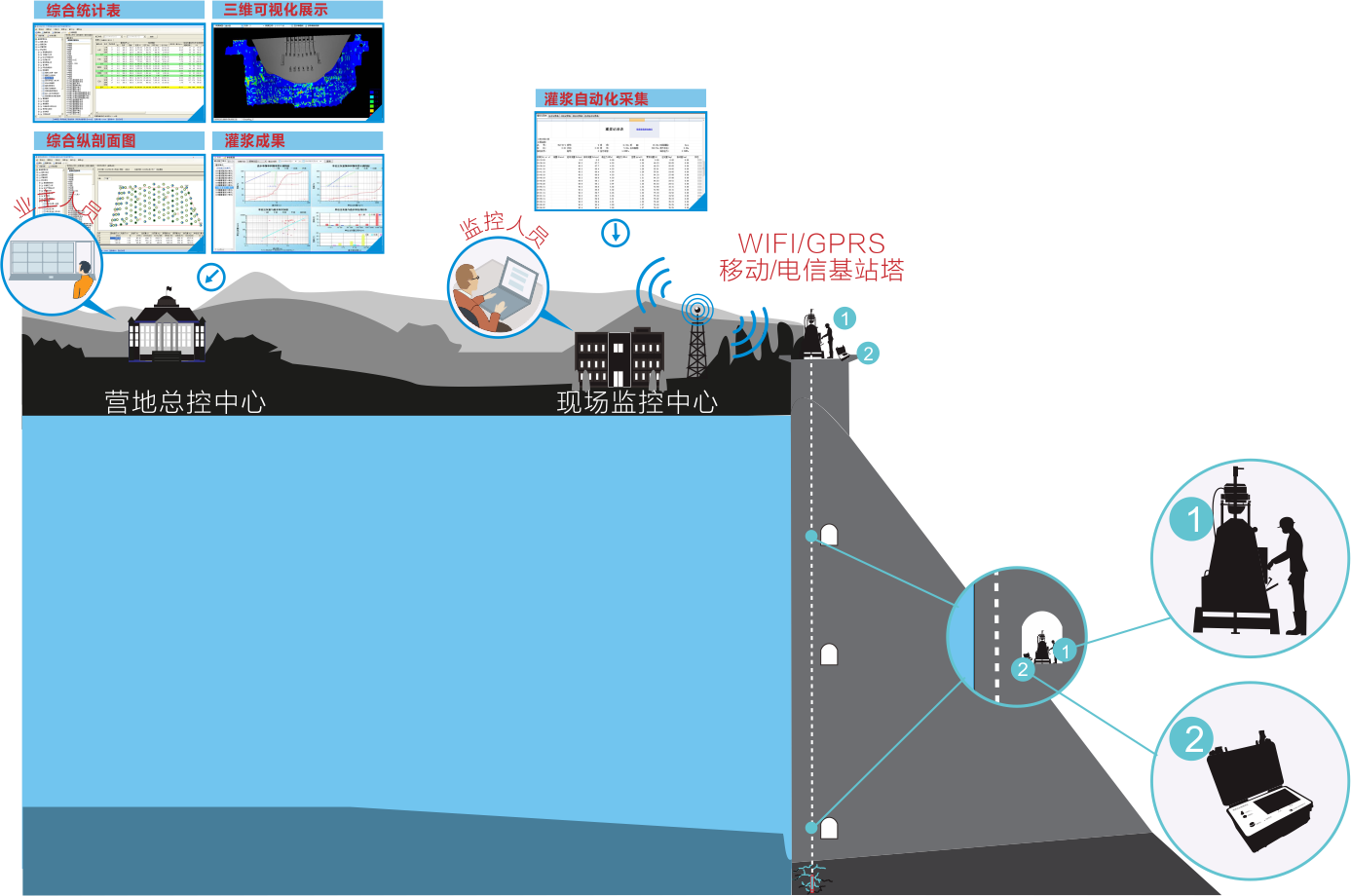

Bedrock Grouting Construction Monitoring System

Monitor grouting quality, master dynamic situation, and send alert for abnormality. Grouting result organization, compatible with market instruments, immediately display of completion outcomes. Special quality analysis, instruction combined with practice, supporting management decision-making.

Value achievements

- It has accepted the protocol of data collection from multiple domestic automatic grouting recorder manufacturers (such as Spring Energy, Institute of Automation under Yangtze River Scientific Research Institute). By connecting with automatic grouting recorders, it can send the real-time data of grouting work to the grouting data and process management database within seconds without human interference, thus ensuring the timeliness and authenticity of data.

- The manager can monitor in real time the working site of grouting from the monitor room at the site or in the camp, timely discover any noncompliance, facilitate fast improvement and rectification, thus achieving fast management and monitoring of the grouting process;

- It provides diversified statement display forms, which seldom requires any additional efforts in sorting. The data outcome is immediately sorted when the grouting work is completed, which evolves the way of sorting grouting outcomes, improves efficiency, and helps the manager solve the problem of metering. The system supports dynamic inquiry of grouting progress, and can reflect the construction data of routine grouting via a 3D image, therefore helping the manager intuitively know about the project progress;

- By using a pertinent grouting quality analysis, it can offer effective and timely guidance, feedback and analysis for grouting, and provide a reliable basis for project managers to make decisions rapidly.

Function Architecture

Related information

Demo video

Scheme manual

There is currently no content information displayed

Star Case

There is currently no content information displayed